RWC (Responsible Welding Coordinator)

The role of an RWC is very important within an organisation this is outlined at the start of the ISO welding coordinator standard ISO 14731.

Your company scope does not need to be complicated as the processes are yours as the manufacturer. The controlling documents should reflect what your company does and be a simple process document (s) that your employees understand and work with on a daily basis.

If you want to discuss WEC representing as your RWC, or you want more information, please contact WEC using the Contact page

This is why an RWC is so important, a quote from the RWC standard

“Welding is a special process, which requires the coordination of welding operations in order to establish confidence in welding fabrication and reliable performance in service. The tasks and responsibilities of personnel involved in welding-related activities (e. g. planning, executing, supervising and inspection) should be clearly defined” BSI London, 2006; EN ISO 14731, p v

RWC (BS EN ISO 14731) & BS EN ISO 3834 Series

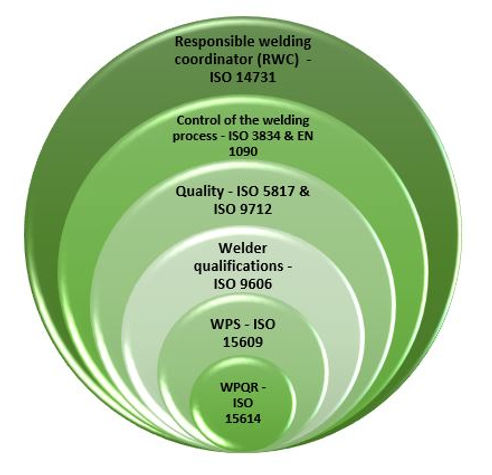

RWC is interlinked with the welding quality accreditation defined by BS EN ISO 3834 series, however please note it is not a Quality Management System (QMS) replacing BS EN ISO 9001, but it is used to help control the inputs and outputs of the welding process working alongside BS EN ISO 9001, not replacing it.

For more information, please contact BWEC using the Contact page